What is difference between Jacobi Carbon and China activated carbon?

Jacobi offers the broadest line of activated carbons in the industry, with hundreds of standard products in granular, powdered, and extruded forms, made from diverse raw materials including coconut shell, various grades of coal, and wood.

Honeycomb Activated Carbon product that has revolutionized vapor phase adsorption applications in industry - including handling of petroleum fuel products at gasoline bulk terminals and refineries. A patented process produces this extruded activated carbon block product with superior adsorptive capacity, high Butane Working Capacity and easily desorbed with heat and vacuum. Suitable for VOC adsorption from paint spray booths, odor control at WWTPs, Air Stripper off-gas etc.

Consider the following features and advantages of using Honeycomb activated carbon over traditional pellet and granular activated carbons:

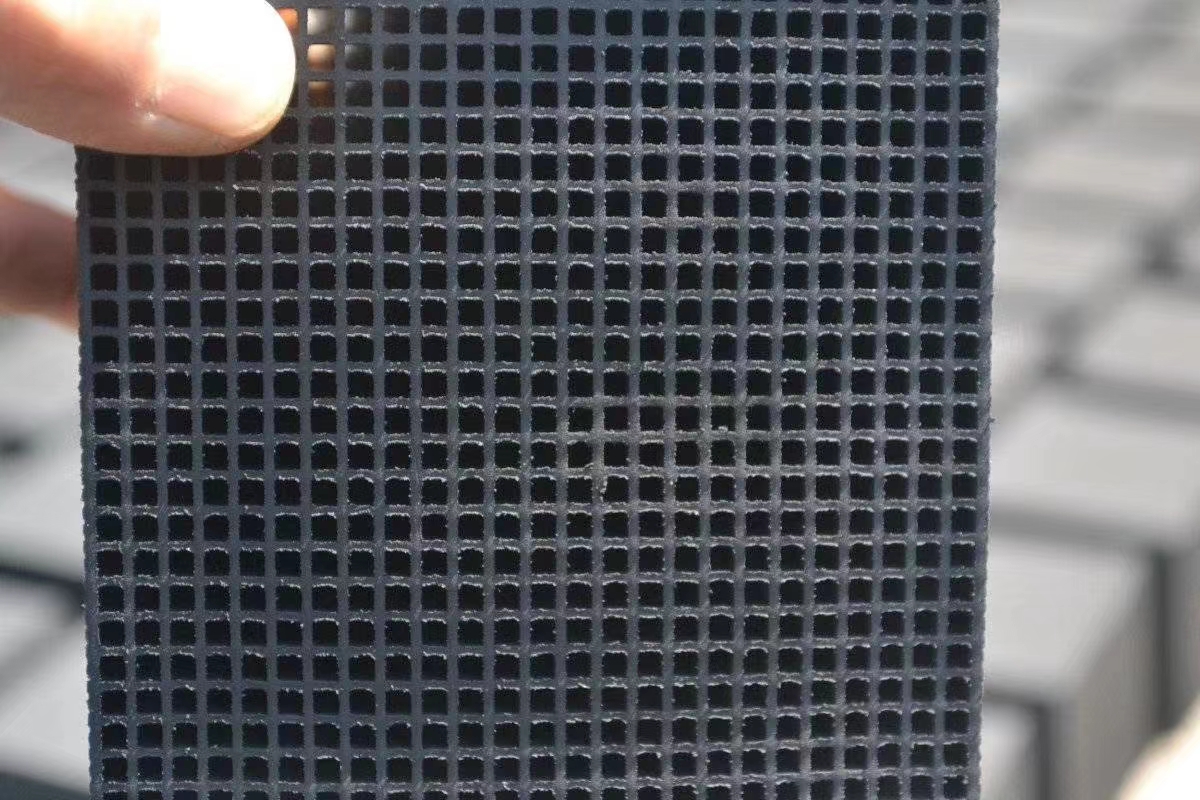

1. The honeycomb structure has a pore size range of 10-2,000 Angstroms and a BET surface area range of ~200-3,000 sq.m/gm!

2. The honeycomb activated carbon is desorbed with liquid ring vacuum pumps and a small quantity of heated condensable compound free air - the adsorbed compounds are stripped!

3. The pressure drop at a given linear gas velocity for Honeycomb carbon block containing 200 cpsi (cells per square inch) is 11 times lower than densely packed 4mm pellet activated carbon!

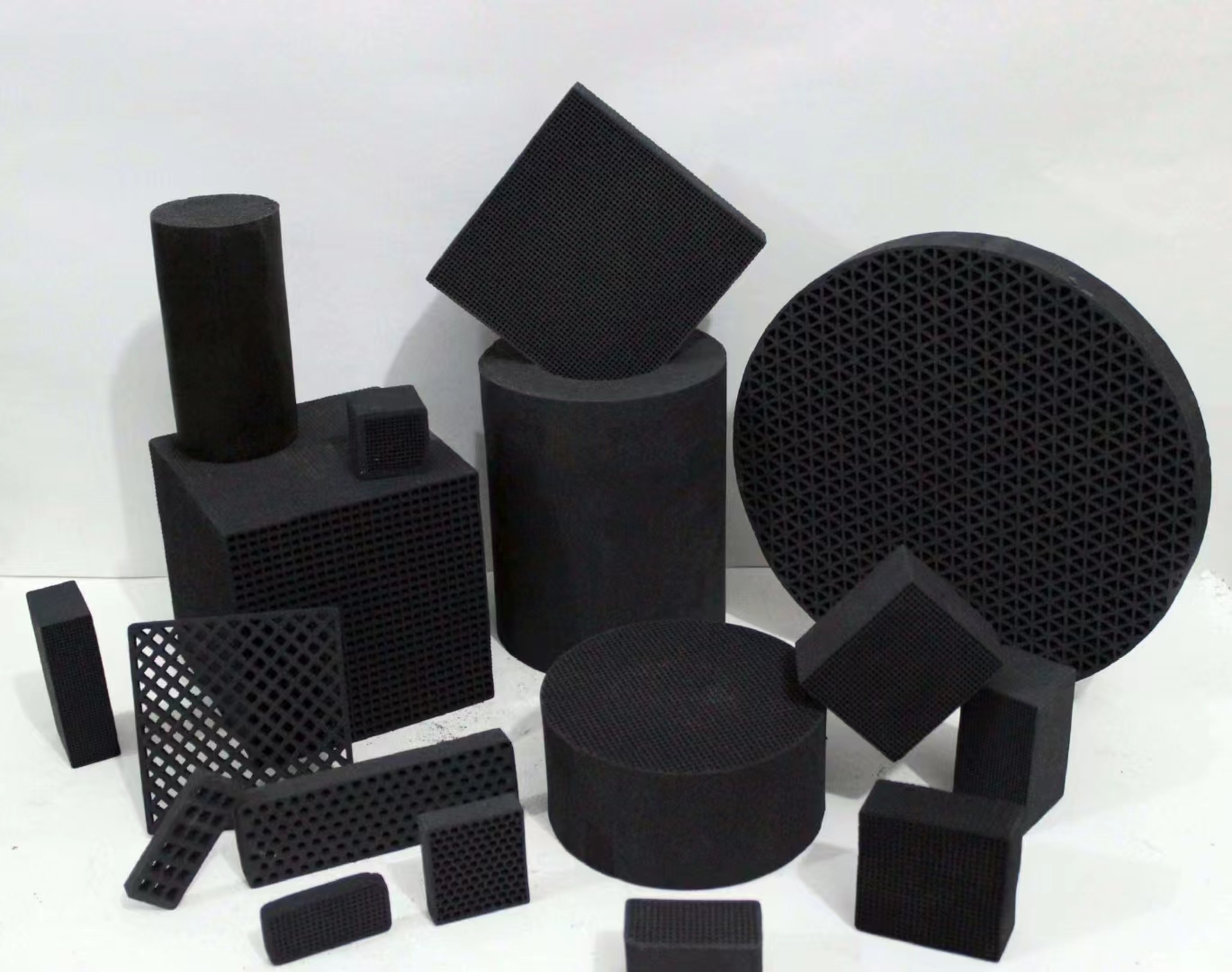

4. Honeycomb activated carbon structures may be pressed into cubes, round cylinders, oval, square and rectangular blocks!

5. The shorter distances for internal diffusion mass transfer for honeycomb activated carbon leads to faster saturation and desorption rates and thus shorter cycle times!

6. Honeycomb adsorbent can be purged of fuel compounds and solvents using a vacuum above 100 mbar!

7. Honeycomb activated carbon has a much higher specific surface area compared to other carbon structures!

8. Honeycomb activated carbon has a lower level of carbon attrition and dust-related problems due to carbon attrition are minimized!

9. Honeycomb activated carbon is available in 100, 200, 300 or 400 cpsi!

10. Honeycomb activated carbon with lower cost than 4mm pellets and has 3 times the surface area for adsorption!!